A bright idea by a former RMWB resident is turning heads in Alberta’s science and engineering field.

NAIT graduate Noah Neiman is a co-finalist for the 2020 Capstone Project of the Year Award from the Association of Science and Engineering Technology Professionals of Alberta (ASET).

Born and raised in Fort McMurray, Neiman and electrical engineering student Sebastian Potoniec from Sherwood Park partnered to develop an automated indoor farming project.

Neiman said it’s an honour for them to earn the nomination.

“It feels great. [There are] lots of other really great projects, even just in my own program, let alone all the different engineering technology programs throughout the province.”

The team of Neiman and Potoniec is one of eight finalists for the Capstone Project of the Year Award.

He said they got the idea after watching a video about an indoor farm.

Neiman said the engineers built the farm within a shipping container to produce food in the city year-round.

“Everything in this indoor farm was fully automated, and we thought it was a really cool idea. We wanted to apply what we were learning in electrical engineering technology and see what it would take to fully automate an indoor farm.”

He said he and Potoniec had 12 weeks to put their idea to paper and design the prototype.

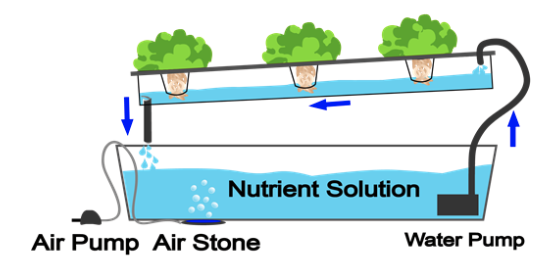

Using the proven Nutrient Film Technique, Neiman said they could control the project through automation.

A study found LED or energy-efficient lighting sources are ideal and would produce the best possible results.

“Every condition for growth of fruit and vegetables is fully controlled, so there is minimal interaction between the farm operator and the indoor plant. Everything is taken care of automatically.”

3D modelling of the lighting aided them in identifying the perfect setup.

Potoniec said as the global population increases, this technology is crucial to human survival.

“The primary goal of our Capstone project was automating an indoor farm. And while automation ideas may not be relevant for most people, it introduces the idea of indoor farming and provides a basic framework on how to accomplish it.”

He added operators may apply the template, which he and Neiman first used for growing lettuce, to a variety of crops, herbs, fruit and vegetables, and flowers.

Neiman said the project is timely as the various countries respond to the COVID-19 pandemic, which put local supply chains at risk.

Neiman added they did not foresee the pandemic when they started work on the project.

“Part of the benefit of automated indoor farming is that it keeps food production local, and it also limits human interaction with the plants. It’s one of the many changes happening in society right now that can hopefully create solutions and improvements in the way we live.”

He said engineers and farm operators may build farms in urban centres reducing costs and reliance on imports.

Neiman said the project would be low-cost, even on a commercial scale.

He added similar projects are already in operation in Edmonton and other places within Alberta.

ASET CEO Barry Cavanaugh said Neiman and Potoniec’s project intrigued him and the nominating committee.

He said automated indoor farming applies the key principles of “Intelligence, Ingenuity, and Innovation”.

“They created a template for significant possibilities for social good, because these indoor farms can be built cheaply, effectively, operated with LED lighting and they can be done anywhere.”

Cavanaugh said engineers could build their scalable project in a room or basement for residents of the Far North, where there are limits to access to fresh crops.

“This ASET Capstone Project of the Year Award finalist project embodies a commitment to sustainability and social responsibility, which is especially vital now given the societal impacts of COVID-19.”

ASET first awarded the Capstone Project of the Year Award in 2017.

Alberta’s engineering schools such as NAIT, SAIT, Red Deer College, and Lethbridge College nominate two teams as finalists for the award.

Cavanaugh said they will announce this year’s winners at the end of August.

ASET represents more than 16,000 members, including full-time technology students, recent graduates and fully certified members.

They also have members in 21 disciplines serving over 120 occupations across various industries.